Project Description

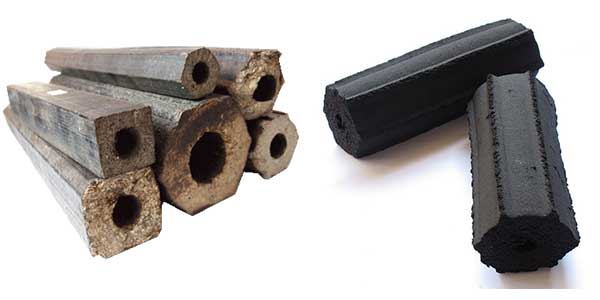

In our briquetting machine production line, screw biomass briquetting machine is the earliest invented briquette machine that can make waste biomass materials into hollow biomass briquettes. The high quality GCBC series screw briquetting machine is the latest model developed by ABC Machinery (the branch company of AGICO) over 6 years of research and development. Because of the hollow structure of biomass briquettes and carbonized layer, the biomass briquettes manufactured by screw briquetting machine are welcomed in India, Thailand, Malaysia and African countries. The briquettes can further be carbonized into charcoal briquettes.

Raw materials for biomass briquetting machines

Screw biomass briquetting machine can process almost all kinds of wood waste, like sawdust, wood shaving and agricultural waste, like peanut shell, coconut shell, palm fiber, stalk, rice husk, and so on.

Functions of Screw Press Briquetting Machine

- Produce heat or electricity for your farm, factory, house, whatever to greatly save your energy bill

- Make money by selling biomass briquettes to companies and individuals

- Alternatively, make charcoal briquettes, a high quality charcoal for BBQ, from wood briquettes or sawdust briquettes with AGICO complete briquetting plant, sell them to supermarket

Specifications of screw briquette machines

| Model | GCBC- I | GCBC-IIA | GCBC-II |

|---|---|---|---|

| Input Raw Material Size (mm) | 3-5mm | ||

| Output Capacity (kg/h) | 180-210 | 300-500 | 300~350 |

| Shapes of Briquettes | Φ=40mm, 50mm, 60mm, 70mm | ||

| Motor Power (kw) | 15kw, 380v, 6 Grades | 18.5kw, 360v, 6 Grades | 22 kW |

| Heating Range | 280~350℃ | ||

| Size of Briquettes Inside Hole | Dia.16mm | Dia.16mm | Dia.18mm/16mm |

| Density of Briquettes | 1.3T/m³ | ||

| Weight (kg) | 700kg | 800kg | 780 kg |

| Overall Dimension(mm) | 2700*600*1600 mm | 2000*600*1700 | 1500*1200*1600mm |

Features of GCBC series screw briquetting machines

- GCBC series briquetting machines have long service life screw shaft that is made from high hardness alloy steel. The advanced processing equipment ensures the srew shafts with no errors.

- The inner former of this machine can be used for 1-2 years. It is made from a whole steel bar with the processing of water jet cutting system; as a result its inner surface is smooth, so that the briquettes are more easily made and saves energy.

- The heating section adopts 2 heat collars that are made from thick copper wires and ceramic inside.

- The forming hopper is added a movable plate at the bottom, so that users can clean it easily and discharge the input material when jammed.

- There is a lubricating system for the gear box. Besides, to make sure the gear box is lubricated properly, there is an exhaust function to maintain consistent air pressure.

- Auto cutting system: with this system, the briquettes can be automatically cut into uniformed length.

Benefits of Biomass Briquettes And Charcoal Briquettes

As biomass briquettes are produced from waste material, such as hardwood, sawdust, corn straw or other biomass feedstock, which makes briquettes sustainable clean energy as substitute of conventional fossil fuel: coal, oil suchlike. In addition, using wood briquettes or biomass briquettes as fuel will not cause pollution at all, meaning that briquettes are sort of preferred solid fuel by countries who have strict demands for environmental protection. When it comes to combustion, biomass briquettes have a longer burning life because of their compactness.

What’s more, biomass briquettes are always produced in regular shapes when equipping with different molding parts, e.g. rectangular, hexagon or round. The well standardized shapes make briquettes easy to store and transport.

While, biomass briquettes, especially wood briquettes that originally extruded from a briquette machine can also be made into charcoal briquettes by a further briquetting process. To get charcoal briquettes, you will have to char the wood briquettes in a kiln, smouldering briquettes in a temperature as high as 1000℃.

Based on charring temperature, 3 type of charcoal briquettes can be seen on market: low temperature charcoal (under 500℃), medium temperature charcoal (under 700℃) and high temperature charcoal (1100℃-1300℃). The higher the temperature where the wood briquettes are charred, the heavier they weight and the better burning performance they have. The high temperature charcoal briquettes that you can make by AGICO charcoal briquetting plant is the highest quality charcoal fuel that are used for exportation, sale and BBQ.